Victor Li, Maximilian Quixk, Moritz Funck

Städtebauliche Vertiefung, CHORA, 2016

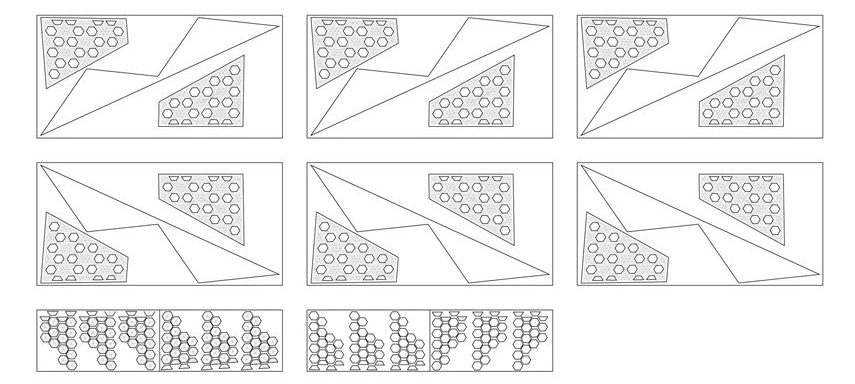

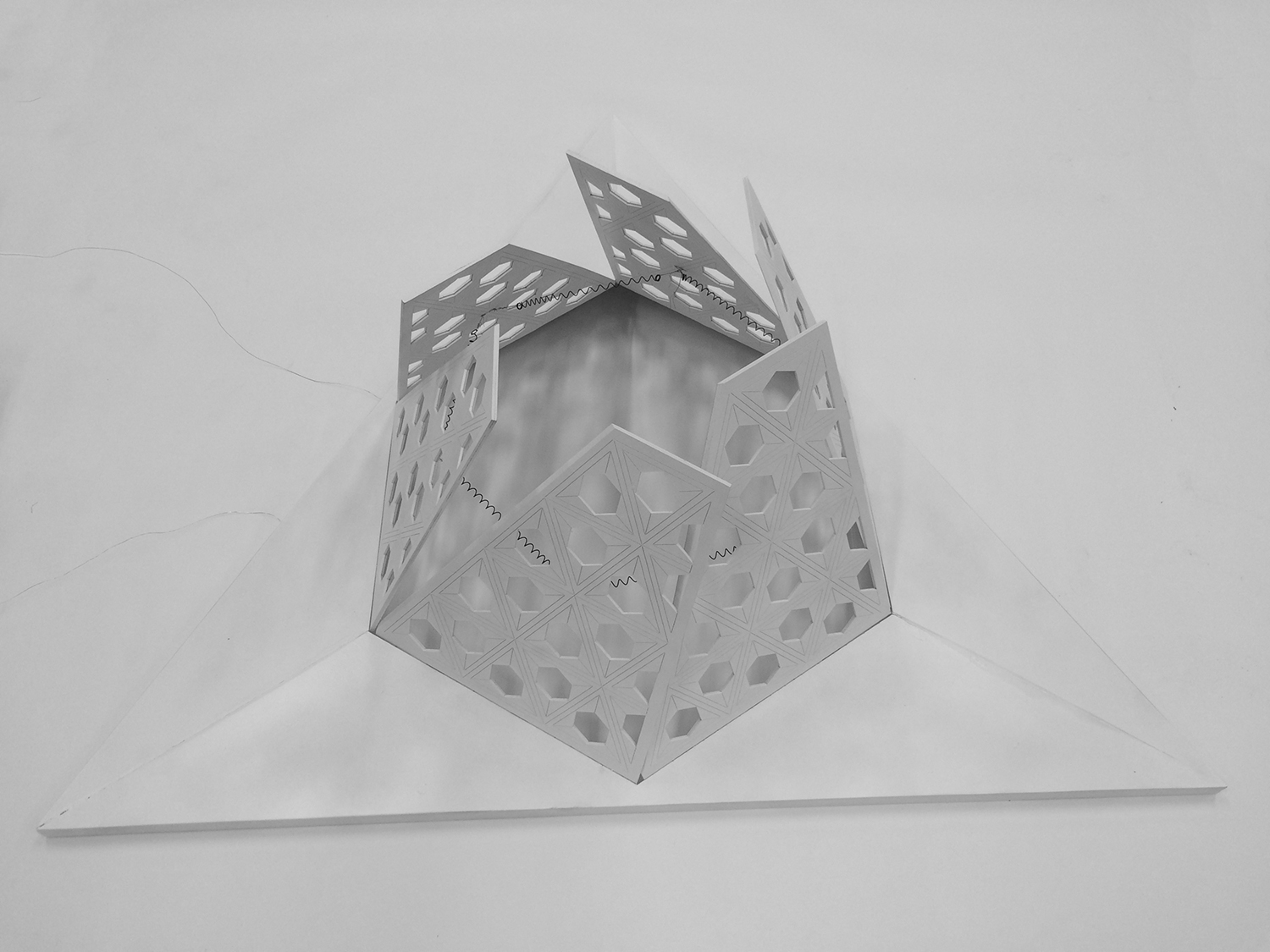

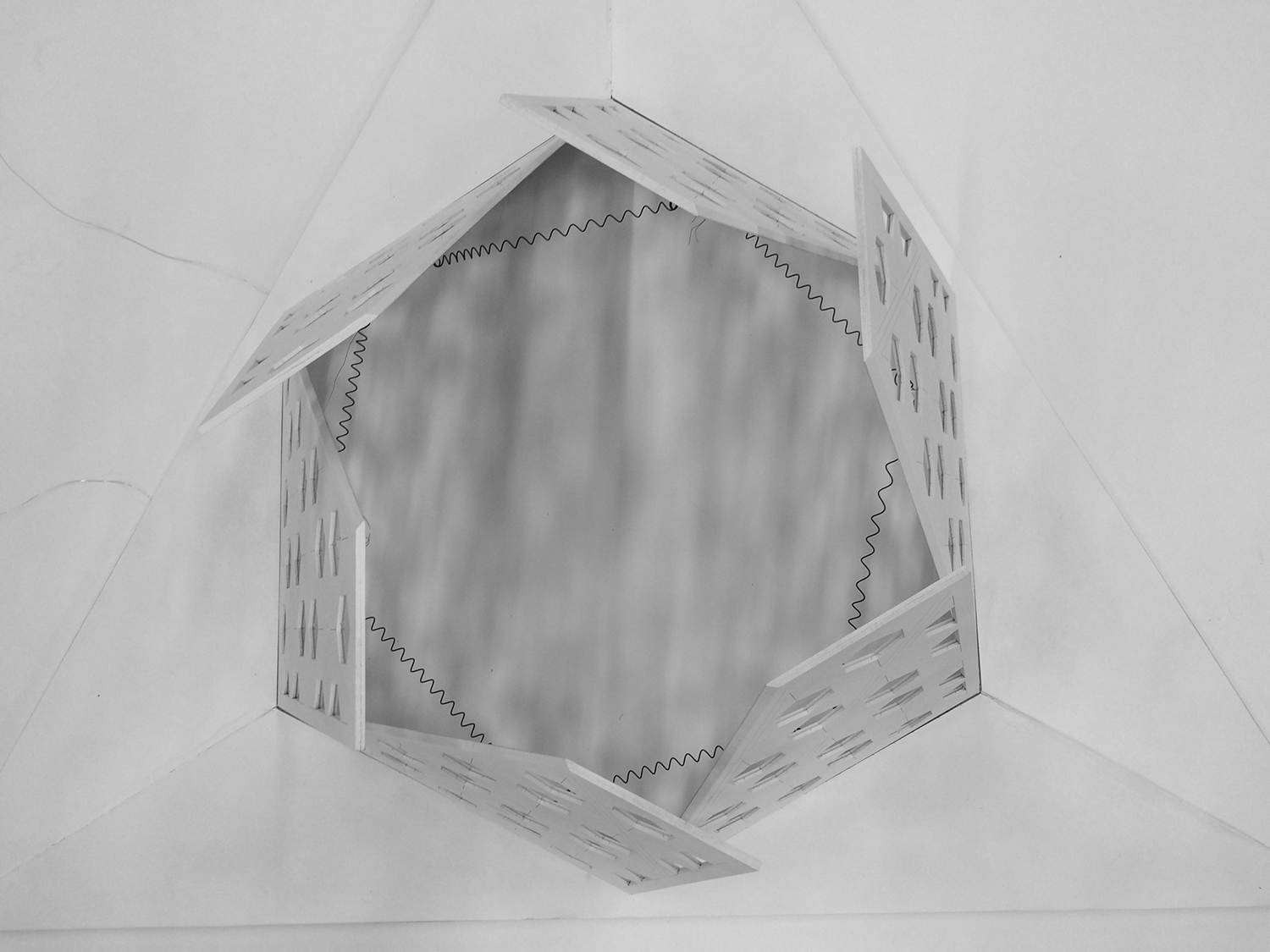

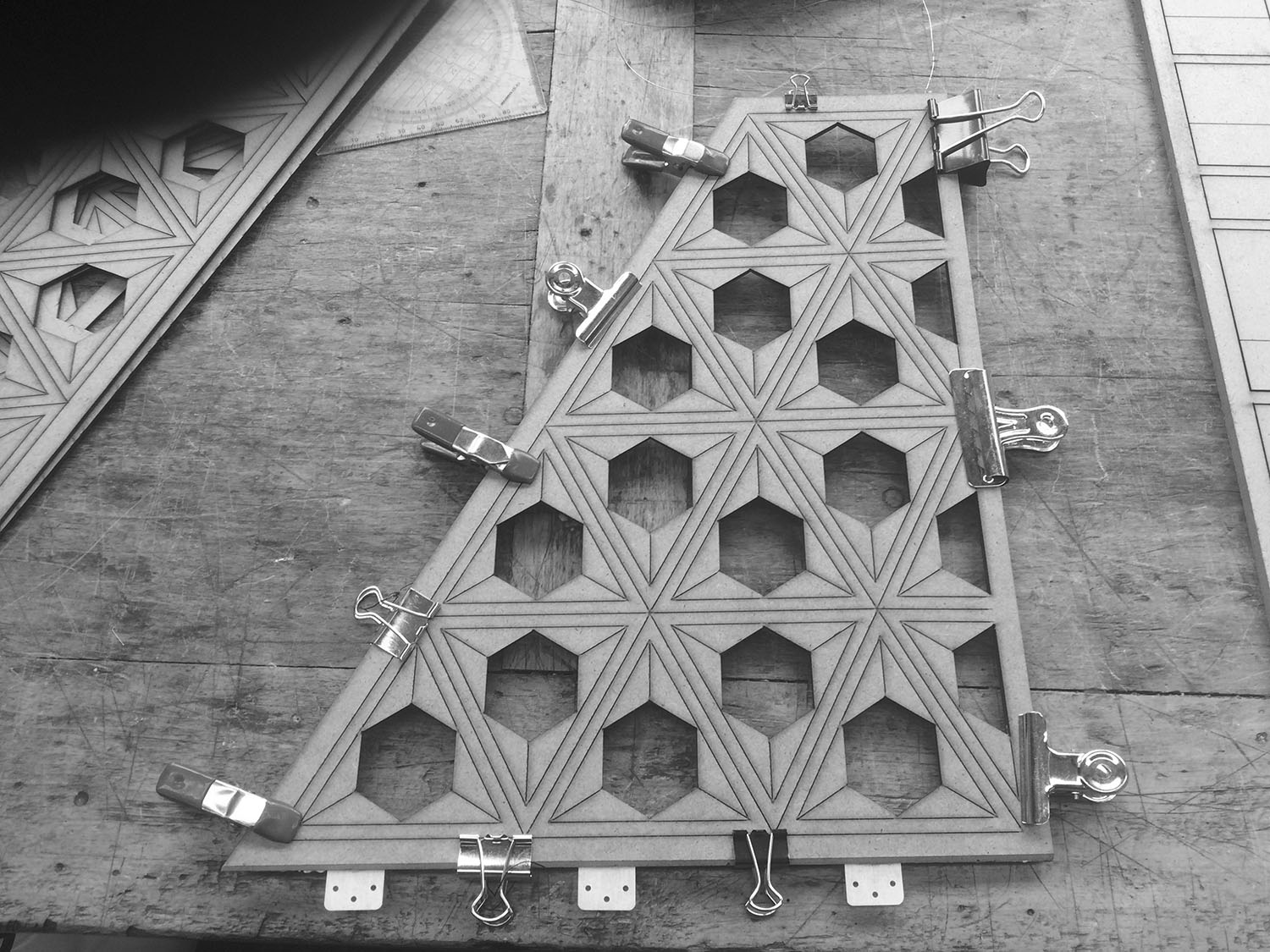

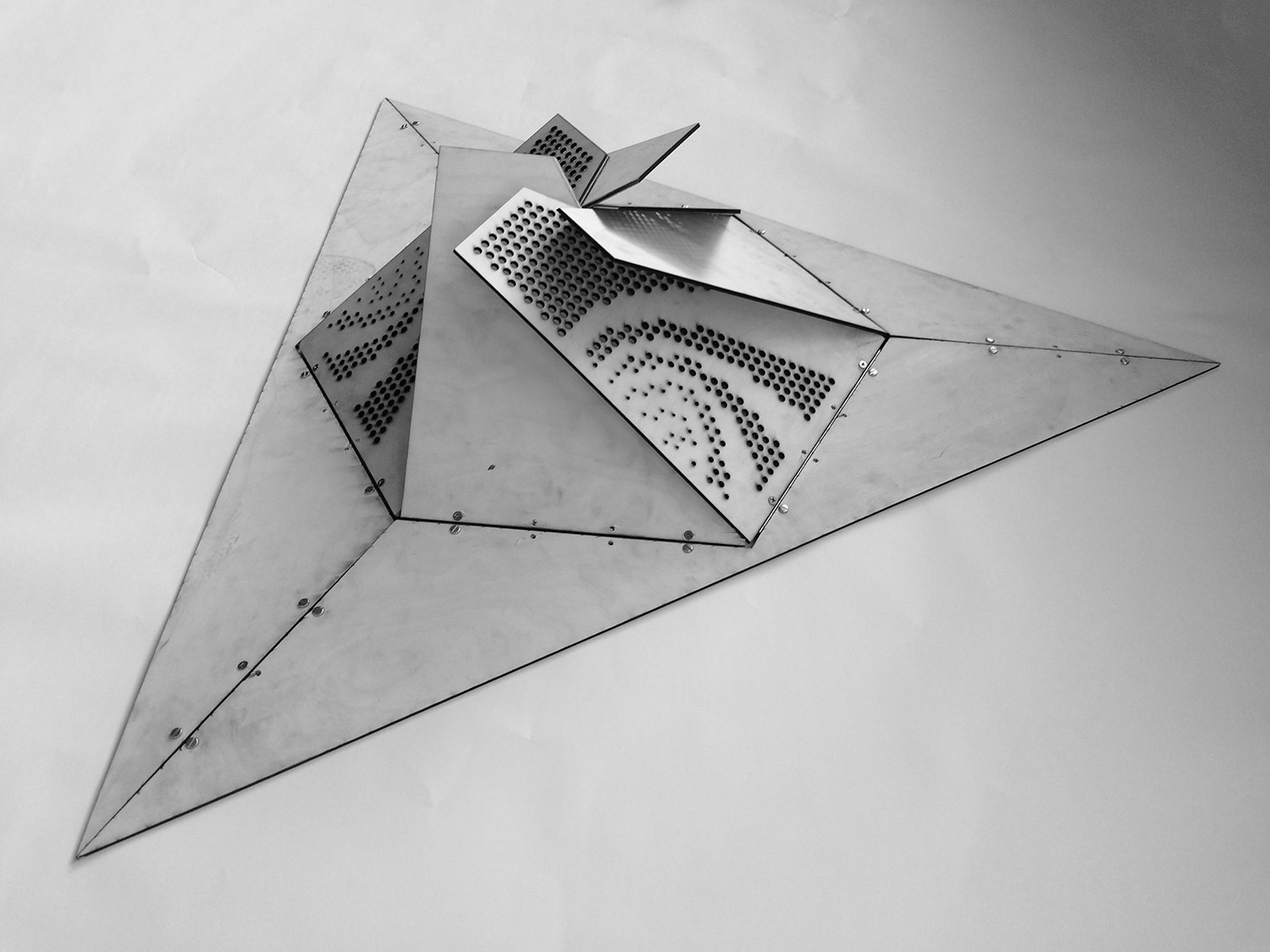

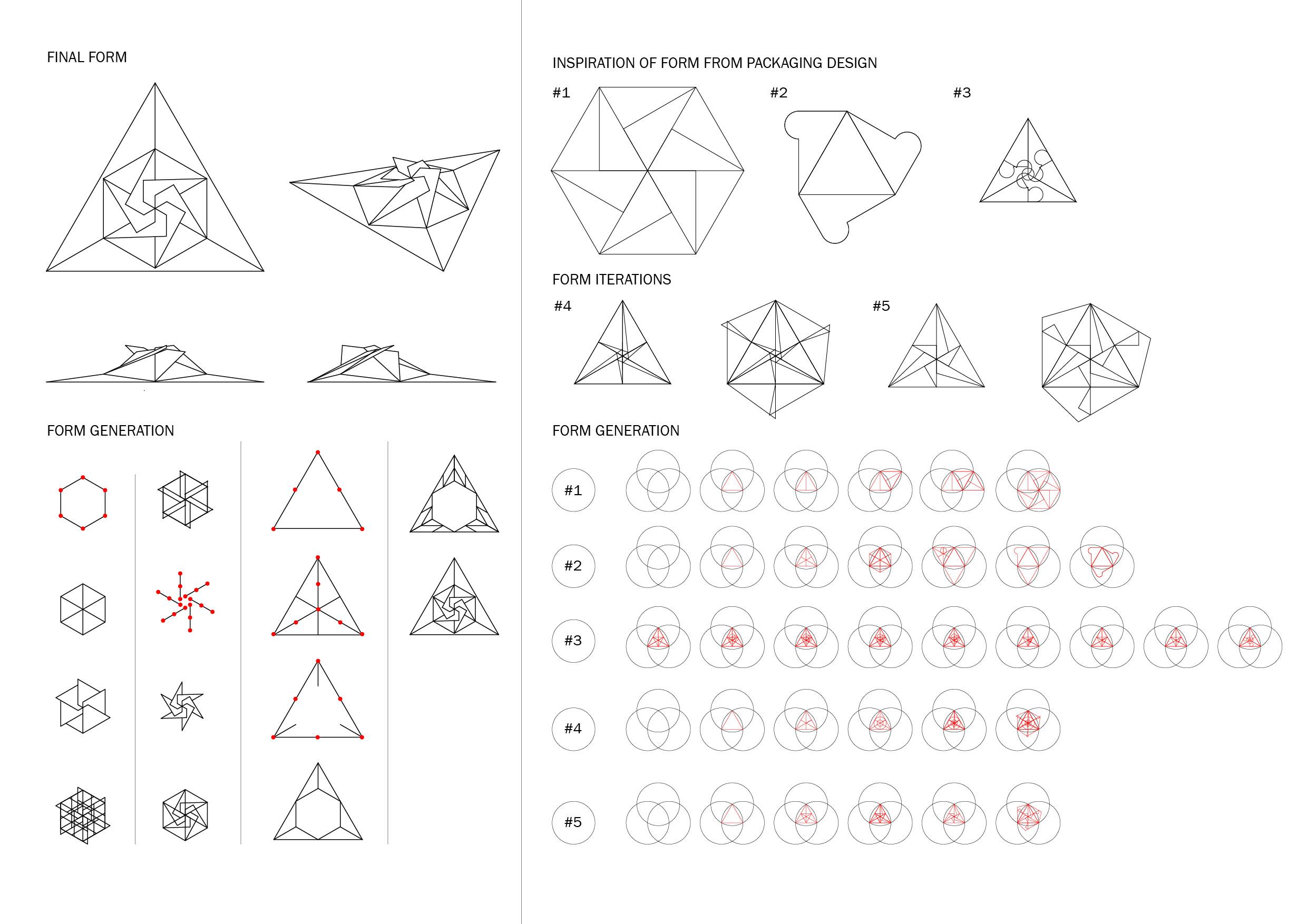

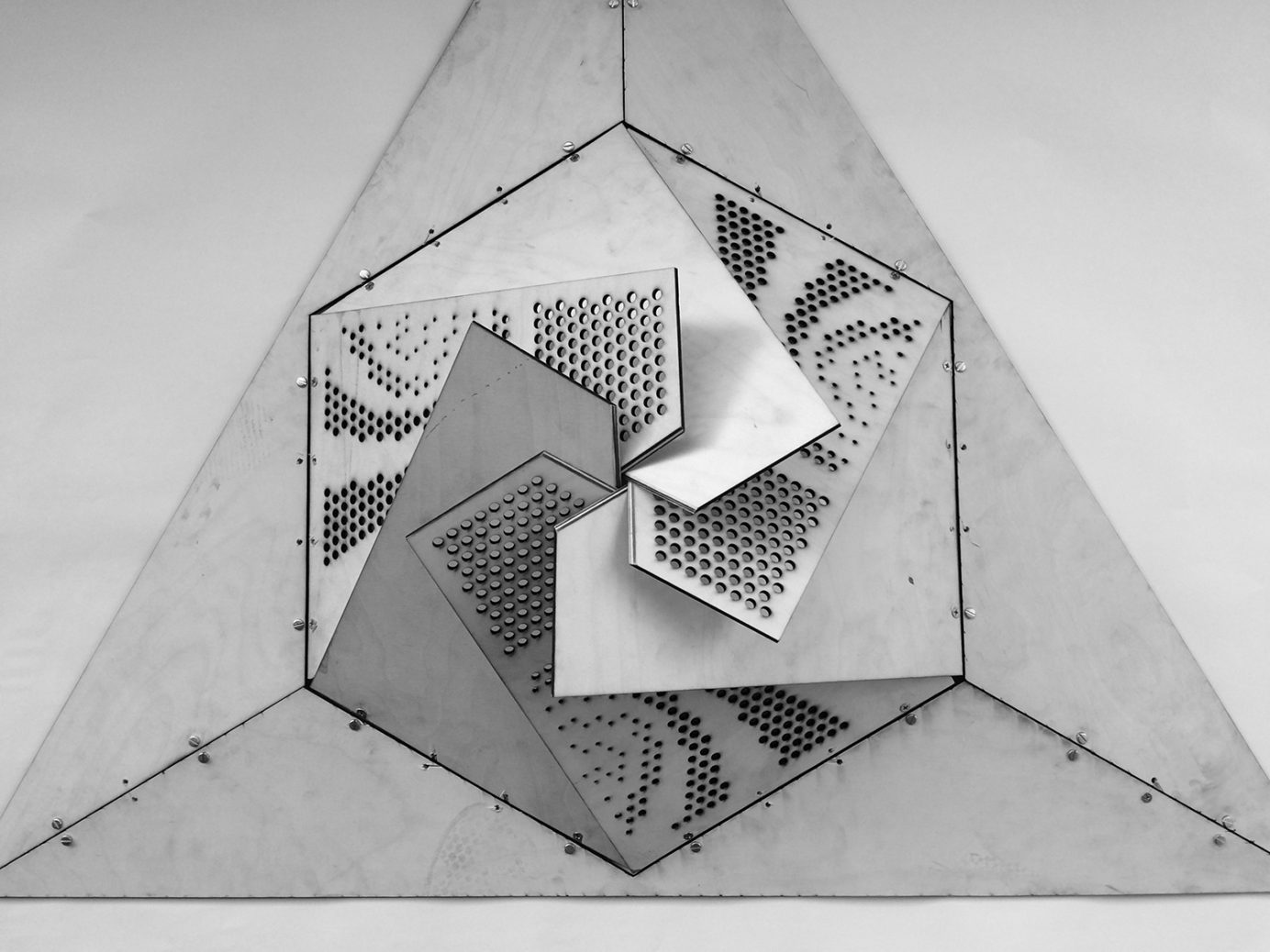

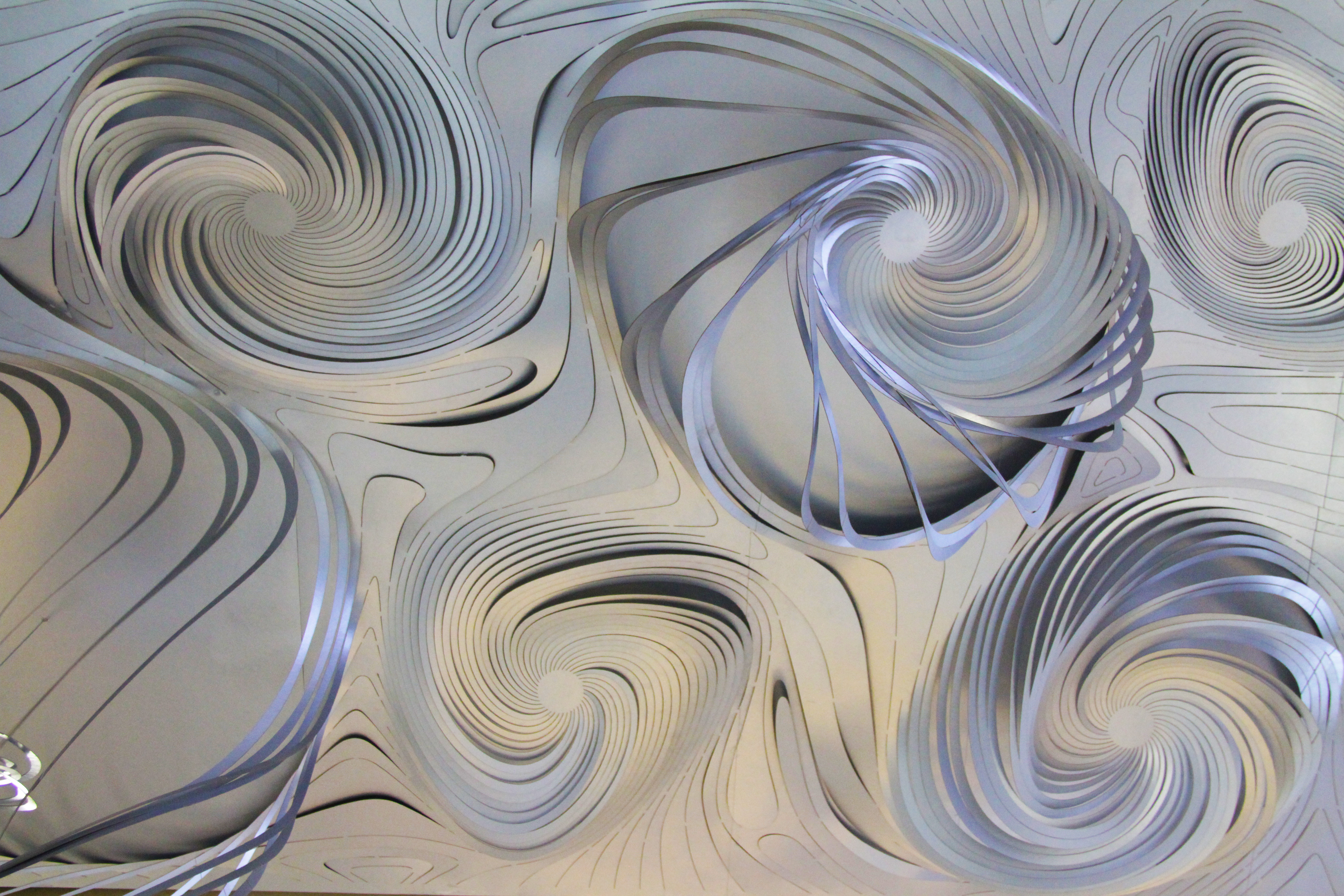

The prototype using ‘shape memory alloy springs’ presents a first prototype for a shading device. It derived from a series of folding tectonics, slotting in the hinges, steel springs and copper wiring between the dual layers of the flaps and base. From the previous prototype of developing only a single wings, now six wings had to be integrated with each other to create a closed circuit to centralise the reaction to an external heat source for a uniform opening and closing movement. To achieve this a loop of copper wire is strung through the punctures in the bottom layer of the flaps as mentioned previously above, then the SMA springs are tied from one wing to the successive wing. The pattern created by this connection once again emerges a hexagonal shape although in a different orientation and scale to the hexagonal arrangement of the wings. The material used to construct the final shading device prototype is largely decided upon the idea pairing with the high-tech, limited accessibility and high cost of the SMA springs with something much more relatively low-tech, that is accessible and affordable. This is in order to inspire more DIY projects to encourage and promote the capacity of SMAs to change our daily life from the bottom up. Thus MDF sheets were used to create the structure of the final prototype, but if the shading device was to be built for commercial application lightweight metal or even bioplastics would be much more recommendable.